ð

In

order to get satisfactory results in dyeing, textile auxiliaries are invariably

employed.

ð

The

use of particular auxiliary in dyeing will depend upon the type of dyestuff and

also on the type of fibre.

ð The important

auxiliaries used in dyeing can be broadly grouped into the following classes:-

(a)

Wetting

and penetrating agents.

(b)

Dispersing

agents.

(c)

Levelling

agents.

(d)

Sequestering

agents.

(e)

Antifoaming

agents.

(f)

Accelerators.

(g)

Migration

Inhibitors.

(h)

Dye

fixing agents.

(i)

After-washing

agents.

(j)

Stripping

agents.

Wetting

and Penetrating Agents

ð Wetting agents are

added to the dye bath to ensure that the entering goods are thoroughly and uniformly

wetted with the dye solution.

ð In this capacity they

are often referred to as Penetrating agents, since they cause the dye solution

to penetrate into the interior of the yarn.

ð It should be noted that

they have little effect on the rate at which dye molecules migrate into the fibre substance.

ð

They also reduce the interfacial tension between oil and water by

adsorbing at the liquid-liquid interface. Many surfactants can also assemble in

the bulk solution into aggregates.

ð

Examples of such aggregates are vesicles and micelles. The concentration at which wetting agent

begin to form micelle is known as the critical micelle concentration (CMC).

ð

When micelles form in water, their tails form a core that can

encapsulate an oil droplet, and their (ionic/polar) heads form an outer shell

that maintains favourable contact with water.

ð

When wetting agents assemble in oil, the aggregate is referred to as a

reverse micelle.

ð In a reverse micelle, the heads are in the

core and the tails maintain favourable contact with oil.

ð In the preparation of

solutions of naphthols and vat dyes wetting agents are used for pasting the

dyestuff.

ð Sulphated oils have

proved to be satisfactory wetting agents in the application of vat and azoic

dyes by padding techniques.

ð The wetting agents help

to prevent dusting off of the materials. The wetting power further increased by

adding electrolytes.

ð The dyeing of polyester

and polyester/cellulosic blends with disperse dyes, the use of wetting agents

is desirable, since polyester fibres being hydrophobic are difficult to wet.

ð Anionic as well as

certain non-ionic wetting agents of polyethylene glycol type are effective in

the dyeing methods wherein exhaustion takes place.

ð In the continuous

thermofixation dyeing of polyester and P/C blends, the selection of a proper

wetting agent is of the utmost importance.

ð Anionic highly

sulphonated oils such as ‘Calsolene oil HSI” have been found to be efficient

wetting agents, while non-ionic wetting agents are less satisfactory.

ð Non-ionic gives less

colour yield because of the formation of complexes with the dye, which have a

lower rate of vapourisation as compared to the dye alone.

ð Sulphated Vegetables

Oils:- Sulphated castor oil (Turkey Red Oil) is a good wetting agent. Its main

constituent is sulphated rincinoleate.

Chemical

Formula of Turkey Red Oil

ð Sulphated Fatty Acid

Esters:- Sulphated methyl oleate (or butyl oleate) is also a good anionic

wetting agent.

ð The most powerful

wetting agent is Dioctyl sulphosuccinate (Octyl being obtained by 2 – ethyl

hexanol).

Me

= Methyl (CH3)

Chemical

Formula of Dioctyl Sulphosuccinate

ð Fatty acid amides and

their derivatives, Alkyl phenol condensates are also good wetting agents.

Dispersing

Agents

ð

The

function of a dispersing agent is to prevent agglomeration of individual dye

particles during dyeing.

ð

Dispersing

agents enhance the dispersion and ensure a fine particle size. It enhances the

processes, by effectively dispersing finely divided solids and liquids in

aqueous environment.

ð

The

nature of dispersing agent depends upon the properties desired and class of the

dyes. It can be of both high and low molecular weights.

ð

Today,

not only do these dispersing agents have a strong dispersing effect, but also

exhibit very high temperature stability throughout the dyeing cycle.

ð

Dispersing

agents are of particular interest in the application of vat dyes by vat acid

and pigment padding methods.

ð

This

product is variously described as sodium salt of a naphthalene sulphonic acid

condensation product (Setamol WS of BASF India Ltd.), aromatic sulphonic acid

condensation product (Uniperse P), disodium salt of methylene dinaphthalene disulphonic

acid (Dadamol V).

Chemical Formula of Dadamol V

ð

These

are available in the form of yellowish brown powder, light beige coloured

powder or dark brown mobile liquid.

ð

The

powder brand is a non-hygroscopic powder that is readily soluble in water with

any degree of hardness.

ð

It is

resistant to alkalis, acids and salts and has dispersing and protective colloid

properties. It is not a surface active agent and hence has no wetting, foaming

and detergent properties.

ð

Being

anionic in nature, it is compatible with anionic and non-ionic products. When

mixed with cationic products, it may form precipitates.

ð

A 10

% solution of the powder has a pH of 6.5 to 7.5 and has good storage stability.

ð

It

finds use in the dyeing of vat, disperse, solubilised vat and azoic colours.

ð

Disperse

dyes are characterised by low solubility in water and in order to ensure

application of these dyes from aqueous liquors dispersing agents are added to

the dyes as they are marketed.

ð

In

addition to this, it is the usual practice to add some dispersing agent to the

dye bath.

ð

Because

of its non-foaming nature, it is recommended for high temperature dyeing.

ð

Anionic

agents such as sodium dinaphthylmethane sulphonates and lingo sulphonates are

generally used as dispersing agent in polyester dyeing.

ð

When

added to the developing baths in azoic dyeing, the dispersing agent increase

the clarity of these baths and yields dyeing of improved rubbing fastness.

Levelling

Agents

ð The levelness of a

dyeing is generally governed by two properties of the dye.

(a)

The

exhaustion behaviour

(b)

The

levelling out capacity (migration power)

ð One of the important

objectives in dyeing is to secure level or uniform dyeing.

ð Many dyestuffs have a

high initial rate of dyeing and show a tendency to rush on to the fibre,

causing uneven dyeing.

ð Levelling agents are,

therefore, added to the dye bath to regulate the process of dyeing and to get

uniform results.

ð A levelling agent

therefore act on the basis of the following two methods:-

(a)

Allow

the dye to go into the fibre, regardless of the initial unlevelness. During the

course of the further dyeing process, the unlevelness is eliminated by

migration.

(b)

Control

the rate of strike of the dye from the beginning so that it does not go on to

the fibre too rapidly.

ð However, during actual

dyeing a levelling agent generally acts in both ways. These agents are

generally used in dyeing polyester with disperse dye and cellulosics with vat

dyes.

ð In the dyeing of wool

with neutral dyeing acid dyes, it is usually difficult to obtain even dyeing.

ð For a long time anionic

surfactant such as fatty alcohols sulphates, fatty amide sulponates and alkyl

aryl sulphonates were used as levelling agents.

ð These agents compete

with the anionic dyestuffs for the available sites in the fibre and thus

procedure uniform dyeing.

ð Fatty alcohol –

ethylene oxide condensates like cetyl alcohol – ethylene oxide, available in

the liquid form are useful as levelling agents in vat dyeing where the dyeing

rate is very large, as in the case of IN class of vat dyes.

ð Anionic products like

dodecylbenzene sulphonates (Na), sulphated fatty acid esters of lower alcohols,

Turkey Red Oil, fatty alcohol sulphates, etc. may be used as levelling agents

in dyeing acid dyes on nylon.

ð They being anionic in

nature compete with the dye anions for the cationic sites in the fibre and

thereby reduce the effective concentration of the dye anions in the dye bath.

ð However, at the later

stages of dyeing, especially at higher temperatures, the levelling

agents anions are replaced by the dye anions

and good colour value is obtained.

ð Cationic

retarders, like Quaternary ammonium compounds generally described as higher

alkyl trimethyl ammonium chloride are useful as levelling agents in dyeing

cationic dyes acrylic fibres.

ð In

the dyeing of cotton by direct dye levelling agents are added which promote

levelling by breaking the dye aggregates which migrate slowly.

ð Cationic

surfactants and non-ionic ethylene oxide condensates levelling agents are used

for vat dye.

ð The

non-ionic levelling agents are more widely used today. These products from

colloidal aggregates with part of the leuco vat dye present in the dye liquor

and thus slow down the dyeing process.

ð Glue

as well as lignin sulphonate products prepared from cellulose sulphite waste

liquors, a by product in the paper – making industry, are also sometimes used.

ð The

levelling agent has to be chosen with reference to the dye used.

Sequestering Agents

ð The

presence of metals as salts of iron, copper, zinc, manganese, tin, aluminium

etc., in the dye bath is highly undesirable as it adversely affects the tone

and brightness of the colour.

ð A

very small amount of these metals can cause appreciable effect on dyeing. For

example, little as one part of iron or aluminium in 10 million parts of water

cause a detectable shade change in certain metallised dyes.

ð Sequestering

agents are useful in any textile operation in which metallic impurities generally

present in hard water interfere in the processing.

ð The

functions of sequestering agents are

(a) Combine

with metallic impurities like calcium, magnesium and other heavy metal ions in

hard water.

(b) They

form molecules in which the ions are held so securely (sequestered) that they

can no longer react.

(c) The

sequestering agents prevent salts from recontaminating parts.

(d) The

sequestering agents may also tie up the active chemicals in a detergent that

may decrease the cleaning efficiency and life of a wash bath.

ð Common

sequestering agents are orthophosphate, orthosilicate and phosphates. These are

available in powder form.

ð Ideal

sequestering agent is H.E.D.P. (Hydroxyehtylene phosphonic acid), as the

chelation value does not drop at scouring temperature, while the worst

performer is citric acid.

Chemical Formula of EDTA

ð The

most effective sequestering agent in dyeing is ethylene diamine tetraacetic

acid (EDTA).

ð Calgon

which is sodium hexa – metaphosphate is often used as a sequestering agent.

Antifoaming Agents

The use of wetting

agents in textile processing liquors, coupled with the rapid movement either

fabric or liquor causing extensive agitation results in the formation of foam

or froth.

Chemical formula of Trimethyl Cyclohexanol

ð This

creates problems in the application of dyes by dyeing, specifically; high speed

padding mangles are prone to foaming.

ð In

order to overcome this problem, antifoaming agents are added to these liquors.

ð In

early days, benzene, pyridine, and turpentine were used as antifoaming agents.

However, their efficiency was found to be inadequate.

ð Most

of antifoaming agents which are more efficient are based on silicones.

ð Dimethyl

polysiloxane, trimethyl polysiloxane are used as antifoaming agents.

ð Yet

another new type of antifoaming agents is based on polyaminoalkyl substituted

organo polysiloxanes in which there are 5-10 amino substituted hydrocarbon

radicals distributed over each 100 silicon atoms in the chain molecules.

ð Fatty

alcohol and lower alcohols, cyclohexanols etc., are used as antifoaming agents.

ð n

– Octanol, 2 – ethyl – hexanol, n - Octyl alcohol, n – Decanol, lauryl alcohol,

oleyl alcohol, trimethyl cyclohexanol are most efficient antifoaming agents.

Accelerators or

Carriers

ð Carriers

are substances which accelerate the rate of dyeing of disperse dyes on

polyester fibre materials when dyed at boil at atmospheric pressure.

ð They

alter the dispersing properties of the dyes and the physical characteristics of

the fibre so that more of the dyestuff can be transferred from the dye bath to

the fibre than in the absence of the carriers.

ð An

ideal carrier should be :-

(a) Availability

at low cost.

(b) Sufficiently

effective in increasing rate of dyeing.

(c) Absence

of unpleasant odour.

(d) Non

– toxic.

(e) Easily

removable after dyeing.

(f) Compatible

with dyestuffs.

(g) Low

volatility

(h) Unlikely

to cause any undue shrinkage of the material.

(i) Little

or no effect on the fastness of the final dyeing.

(j) Preferably

biodegradable.

ð Carriers

are mainly based on phenyl phenol (ortho and para) and di – or

trichlorobenzenes.

ð Orthophenyl

phenol may be used in the concentration range of 3 to 6 gpl. The free phenol is

insoluble in water and difficult to disperse in water.

ð To

overcome this defect, its sodium salt is used, but has no carrier action. The

free phenol should be liberated in the dye bath by the addition of acid –

liberating agent.

ð This

carrier adversely affects the light fastness of the final dyeing if not

completely removed from the dyeing.

ð Di

– and trichlorobenzenes are good carriers which promote dye absorption by the

fibre and the residual carriers do not affect the fastness of the final dyeing.

ð These

water insoluble carriers have to emulsify in the dye bath using an emulsifying

agent such as anionic detergent (alkyl benzene sulphonate).

ð These

carriers are toxic in nature and their use involves use of enclosed dyeing

machine.

ð Monomethyl

naphthalene has less powerful carrier action and is suitable only for dyeing

rapidly diffusing dyes. It is readily biodegradable.

ð Dimethyl

ester or Terephthalic acid possesses many desirable properties of an ideal

carrier but it has only moderate odour and it is costly.

ð Methyl

cresotinate is an efficient carrier and has no adverse effect on the light

fastness of the dyes. It is however expensive and volatile.

ð Butyl

benzoate is only moderate efficient in increasing the uptake of disperse dyes.

It is employed for promoting levelling in the high temperature dyeing of

polyester. It has a powerful odour.

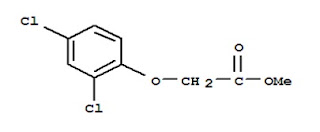

ð Methyldichlorophenoxy

acetate is a very efficient carrier with little odour, can be easily removed

from the dyed material. It is however very expensive.

Me = Methyl

Chemical

Formula of Methyldichlorophenoxy acetate

ð N

– Alkylphthalimide derivative has good efficiency, little odour and low

toxicity. Due to its ease of removal, it is especially useful in garment

dyeing.

Migration Inhibitor

ð Today,

continuous dyeing of textile fabrics are becoming more popular compare to batch

methods due to higher rate of production.

ð Continuous

dyeing methods require fabric to be dried after padding and before developing.

This step is known as intermediate drying.

ð Intermediate

drying is carried out on hot air machine, or drying cans. These machines for

drying operate by evaporating water from the fabric surface.

ð During

the passage of the fabric through the machine, the surface water is removed as

vapour and more water is drawn from the interior to the surface to restore

equilibrium between liquid and vapour.

ð Migration

of the dye particles to the surface may occur as a result of this movement of

water and lead to lack of penetration.

ð Also

differences in the rate of drying of the two faces of a fabric would give a two

– sided appearance because of unequal amount of dye, on the two surfaces.

ð This

difficulty of uneven dyeing due to migration can be avoided by the use of

migration inhibitors and also by careful drying.

ð In

the dyeing of vat dyes by the continuous pigment pad method migration

inhibitors such as common salt, glauber’s salt, sodium bisulphite, sodium

acetate and various thickeners such as gum tragacanth, sodium alginate are

added to the padding liquor.

ð Sodium

alginate, when neutral and very carefully prepared in concentration up to 1 g/l

is probably the most satisfactory. Sometimes carboxy methyl cellulose is

employed.

ð ICI

has recommended migration inhibitor V, which is said to be an organic anionic

polyelectrolyte. It produces level results and better colour yield.

ð Reactive

dyes are widely applied on cellulosic fabrics by continuous methods. In this

case migration inhibitors recommended are based on non – ionic

polyelectrolytes.

ð In

the thermosol process of applying disperse dyes to polyester/cellulosic

fabrics, it is absolutely necessary to have even distribution of the dyestuff

on the fabric prior to thermofixation, so migration inhibitors are added to the

padding liquor to prevent migration of dyestuffs during drying.

ð An

inhibitor to be suitable for thermosol process, should have the following

properties:-

(a) The

solid content of the additive should be as low as possible.

(b) It

should not affect the solubility or dispersion of the dyestuff.

(c) It

should prevent migration but should not hinder the diffusion of dye into fibre.

(d) It

should be resistant to high temperature.

(e) It

should be easily removable after dyeing.

Dye Fixing Agents

ð The

main drawback of direct cotton dyes is that their fastness to washing and

soaping is poor.

ð Attempts

have been made to develop some after-treatments which can improve the fastness

properties of these dyes on cellulosic fibres.

ð Cationic

surface active agents such as Fixanol C, Sandofix, Lyofix DF, Sapamines and

Hicofix GL are commonly used for this purpose.

ð This

after-treatment improves the fastness to water, acids and alkalis, but the

treated dyeing shows little or no improvement in solution of soaps or

detergent.

ð It

is known that these products function by forming a complex between the dye

anion and the cation of the agent.

ð The

complex being less soluble than the dye anion shows increased wet fastness.

ð This

complex, however, is broken down by anionic surface active agents leading to

poor fastness to soaping.

ð During

the dyeing of cotton with reactive dyes, two reactions proceed simultaneously

under alkaline conditions.

ð One

is the reaction of the dye with hydroxyl groups of cellulose, leading to the

fixation of dyestuffs, and the other is the reaction with hydroxyl groups of

water leading to the formation of the hydrolysed dye.

ð This

hydrolysed dye should be completely removed by soaping, as otherwise wash

fastness properties will be poor.

ð An

after-treatment with cationic agents such as Fixanol PN, has been suggested to

increase the fastness of the hydrolysed dye.

ð In

this case, the colour yield is also increased because the hydrolysed dye is

attached to the fibre by the cationic agent.

ð Recently,

an after-treatment with a base containing at least one primary or secondary

amino group e.g. diethanolamine has been also suggested for this purpose.

After Washing Agents

ð On

completion of dyeing, with most dyes it is usual to give an after-treatment

with a surfactant which is termed soaping, since soap was used for this

purpose.

ð Today

along with soap, a number of anionic and non – ionic surfactants are available

for this purpose.

ð In

the dyeing of cotton with vat dyes, soaping causes the aggregation of dye

particles, helps in developing true shades and removes surface dyestuff from

the fibre.

ð Soaping

is very important in azoic dyeing as it helps to improve the rubbing fastness.

ð In

case of the reactive dyes, soaping is important in order to remove unfixed

hydrolysed dye from the material and to obtain dyeing with satisfactory

fastness properties.

Stripping Agents

ð It

is sometimes necessary to remove the dye from dyed material in order to correct

the faulty dyeing. This process is called stripping.

ð The

primary requirements of a successful stripping methods are:-

(a) The

process must effectively remove the dyestuff

(b) The

fibre must remain substantially unimpaired so that it can be redyed to a

saleable item

(c) The

cost must be low.

ð Stripping

of direct dye on cotton is simple and consists essentially of treatment of the

material with either alkaline hydrosulphite or sodium chlorite.

ð Stripping

of vat dyes is difficult. An effective stripping agent for vat dyes must remove

the leuco compound as it is formed and leach it out into the bath, thus

preventing a re-adsorption on the fabric.

ð Cationactive,

long chain quaternary ammonium salts such as Lissolamine A and Lissolamine V

are found to be effective in stripping of vat dyes.

ð A

new agent based on polyvinyl pyrrolidone sold under the trade name Albigen A is

recommended for stripping vat, sulphur and direct dyes.

ð Stripping

of vat dyes is also achieved by using alkali and formamidine sulphinic acid,

prepared by the action of hydrogen peroxide on thiourea at near boiling point.

ð In

the stripping of azoic dye, certain quaternary ammonium compounds such as cetyl

trimethyl ammonium bromide in presence of alkaline reducing agent have been

found very effective.

ð Acid

dyes can be stripped from wool by treatment with acidified sodium sulphoxylate

formaldehyde, often in presence of a little formaldehyde.

ð Disperse

dyes from nylon are stripped by using either a mixture of non – ionic detergent

and polyvinyl pyrrolidone or sulphoxylate formaldehyde activated by acetic or

formic acid in presence of benzyl alcohol.

ð The

acid dye from nylon is stripped by using a mixture of trisodium phosphate and

non – ionic detergent, often in presence of benzyl alcohol.

ð Stripping

of disperse dyes from polyester is extremely difficult. Treatment with carrier

such as chlorinated benzene or salicylic acid is useful for partial stripping.

ð For

stripping deep shades on heat-set polyester, the following method is

recommended:- treat with carrier, zinc sulphoxylate and acetic acid at boil,

for 60 minutes, followed by a wash and another treatment with carrier sodium

chlorite and oxalic acid at boil for 45 minutes.