- Meltblowing is a process for

producing fibrous webs or articles directly from polymers or resins using

high-velocity air or another appropriate force to attenuate the filaments.

- This one is a recent

technique developed in nonwoven manufacturing.

- The advantage of this process

is its ability to produce microfiber webs having diameters ranging from

0.1 mm to 15 mm, from which diameters 2-4 mm are popular.

Raw Materials

The

meltblown process has no or little orientation after extrusion. Hence many

polymers apart from Polypropylene and Polyester can be processed:

1) High-density polyethylene (HDPE), Low-density polyethylene (LDPE), LLDPE

2)

Polyamides (PA 6, PA 6.6, PA10)

3)

Polystyrene (PS)

4)

Polytrifluorochloroethene (PCTFE)

5)

Polycarbonate (PC)

6)

Polyurethane (PUR)

Meltblown

Process

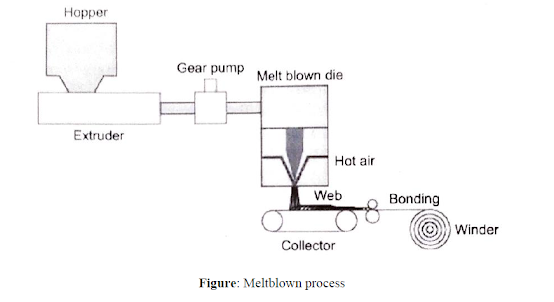

Meltblowing is a single-stage process in which high-velocity air blows a molten thermoplastics resin an extruder die tip onto a conveyor or take-up screen to form a finely fibrous and self-bonding web as below:

The components of meltblowing process are:

- Extruder: from the hopper feeder, the polymer chips are feds to the Archimedean screw, which rotates inside the cylinder; due to this rotation chips are forwarded to the hot walls of the cylinder, so the polymer melted by heat and frictional forces. The screw is divided into feed, transition, and metering zone.

ð The

feed zone preheats the polymer pellets.

ð Transition

zone compresses and homogenizes the melting polymers.

ð Metering

zone serves to generate maximum pressure for extrusion.

- Metering Pump: It controls the delivery of the melt to the die assembly ensuring a consistent flow of polymer with the required pressure, temperature, and viscosity. It is designed with two intermeshing and counter-rotating toothed gears.

- Die Assembly:

ð Feed Distribution: It distributes the flow evenly to all the spinnerets flow and ensures constant residence time across the width of the die in all instances. There are two types of feed distribution, one is T-type and another is coat hanger type (widely used).

ð Air Manifolds: The die nosepiece is designed with slots through which the air manifolds supply the high-velocity hot air. Generally, the temperature of 230˚C to 360˚C and air velocities of 0.5-0.8% of the speed of sound.

ð Die Nosepiece: The design of the die nosepiece is responsible for web uniformity. It is typically a hollow and tapered piece of metal having a linear arrangement of several hundred orifices along its width. The polymer melts extruded through these holes and the emerging filaments are quenched using hot air. The dimension of the nosepiece includes a diameter of 0.4 mm and the number of orifices per mm ranges from 1 to 4.

- Web Formation:

Extruded polymers passed through the die holes, hot air streams of high

velocity, and the die nosepiece to form microfibers. The hot air stream

directs the microfibers to a collecting screen. On the way to the same

screen, the secondary air cools and solidifies the fibers. Due to random

deposition of fibers, they entangled themselves, and hence air turbulence

forms a self-bonded nonwoven web. The collector speed and the distance of

the die nosepiece from the collector screen are playing major roles in

producing different types of meltblowns. The hot air lying on the fibers can

be withdrawn by applying a vacuum inside the collector screen.

- Winding: The web is wound onto a cardboard core and processed according to the end-use requirement.

- Bonding: To improve the fiber adhesion and web characteristics, the web may be subjected to additional bonding processes like thermal bonding. Either area bonding (overall) or pattern bonding (spot) techniques can be adapted, which improves the web strength and abrasion resistance.

- Finishing:

This treatment is not mandatory, finishing treatments like calendaring,

embossing can be performed at the end of the production line.

- The process variables are divided into

two categories such as operational/online and offline variables.

Web

Characteristics and Properties

- The distribution of fiber in

the air stream and the vacuum settings below the collecting screen

determine the web uniformity.

- Non-uniform distribution can

be caused due to poor die design and improper airflow in the air stream.

- The vacuum under the collector

should be capable of withdrawing the entire air stream through the perforations

and randomly locking the fibers in place.

- As the distance between the die

and the collecting screen increases, the web uniformity decreases.

Product

characteristics

ð Random

fiber orientation in the web

ð Lower

to moderate web strength

ð High

opacity

ð Low

GSM material

ð Fiber

diameter ranges from 0.5 to 30m, but typically 2-7 m

ð Basis

weight ranges from 8 – 350 g/m2, but typically 20 – 200 g/m2

ð Good

insulation and filtration characteristics

ð Smooth

and soft surface texture and are circular in cross-section

ð Layered structure, the number of layers increases with basis weight.

Application

|

Medical

fabrics |

|

|

Adsorbents |

|

|

Filtration

media |

|

|

Apparel |

|

|

Electronic

specialities |

|

|

Miscellaneous |

|

References

- Karthik

T., Prabha Karan C., and R. Rathinamoorthy (2016), Non-woven - Process,

Structure, Properties and Applications, Woodhead Publication India, pp. 80-86.

- Giovanni Tanchis (2008), The nonwovens, ACIMIT.

- Lokesh K V (2013), Meltblown nonwoven, www.textilelearner.blogspot.com